Jan 2024 - Present

Abstract: High entropy alloys (HEA) have attracted attention due to their potential for high temperature applications. Nanowires were fabricated from an equiatomic CrMnFeCoNi high-entropy alloy using an alumina mold with nanocavities. The growth mechanism was found to involve both dislocation slip and interface diffusion, depending on temperature, while bulk diffusion, though considered, was not observed. The goal of this research is to analyze the effects of temperature, pressure, and mold dimensions on nanowire composition, length, and structure, providing insights into interdiffusion among alloy elements. Additionally, the interfaces between the feedstock alloy, alumina mold, and the resulting nanowires were examined using Scanning Electron Microscopy. These findings pave the way for fabricating high aspect ratio nanowires from high-entropy alloys and offer a deeper understanding of their rapid and sluggish diffusion behaviors. I investigate and characterize the Cantor Alloy’s (CoCrFeMnNi) diffusion behaviors.

Overall Procedure

Mini act melting alloy together

-

The alloy is melted together in an arc melter, trying to keep a homogenous and equiatomic alloy

-

The sample is then cold roled and polished in order to prepare it for nanomolding. Nanomolding places the sample under high temperature and high pressure conditions to enable diffusion

-

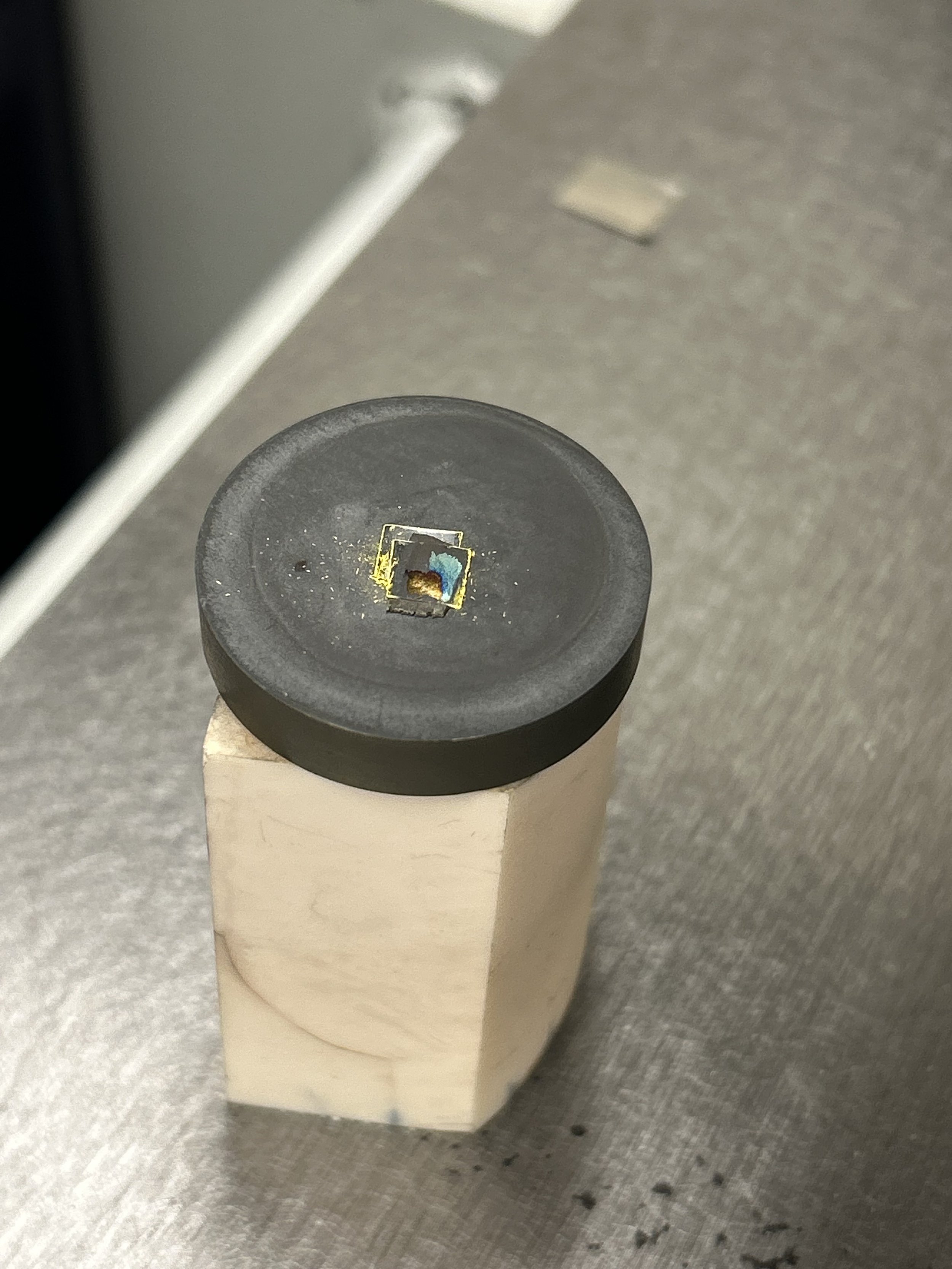

After producing nanorods, we characterize their properties using Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)

I fabricate and characterize the Cantor Alloy’s metallic nanowires grown via thermomechanical diffusion-based molding. Prepare bulk alloys via arc-melting, cold-working, annealing, and polishing; imaged via SEM-EDX, EBSD. Designed experimental apparatus and protocol for high-temperature (~800C), high-pressure (>1GPa) molding. Analyzed nanowire growth and composition to infer elemental inter-diffusion behaviors. While continuing to finalize results, it is highly speculated that not every element diffuses at the same rate.

TEM Images Coming Soon!

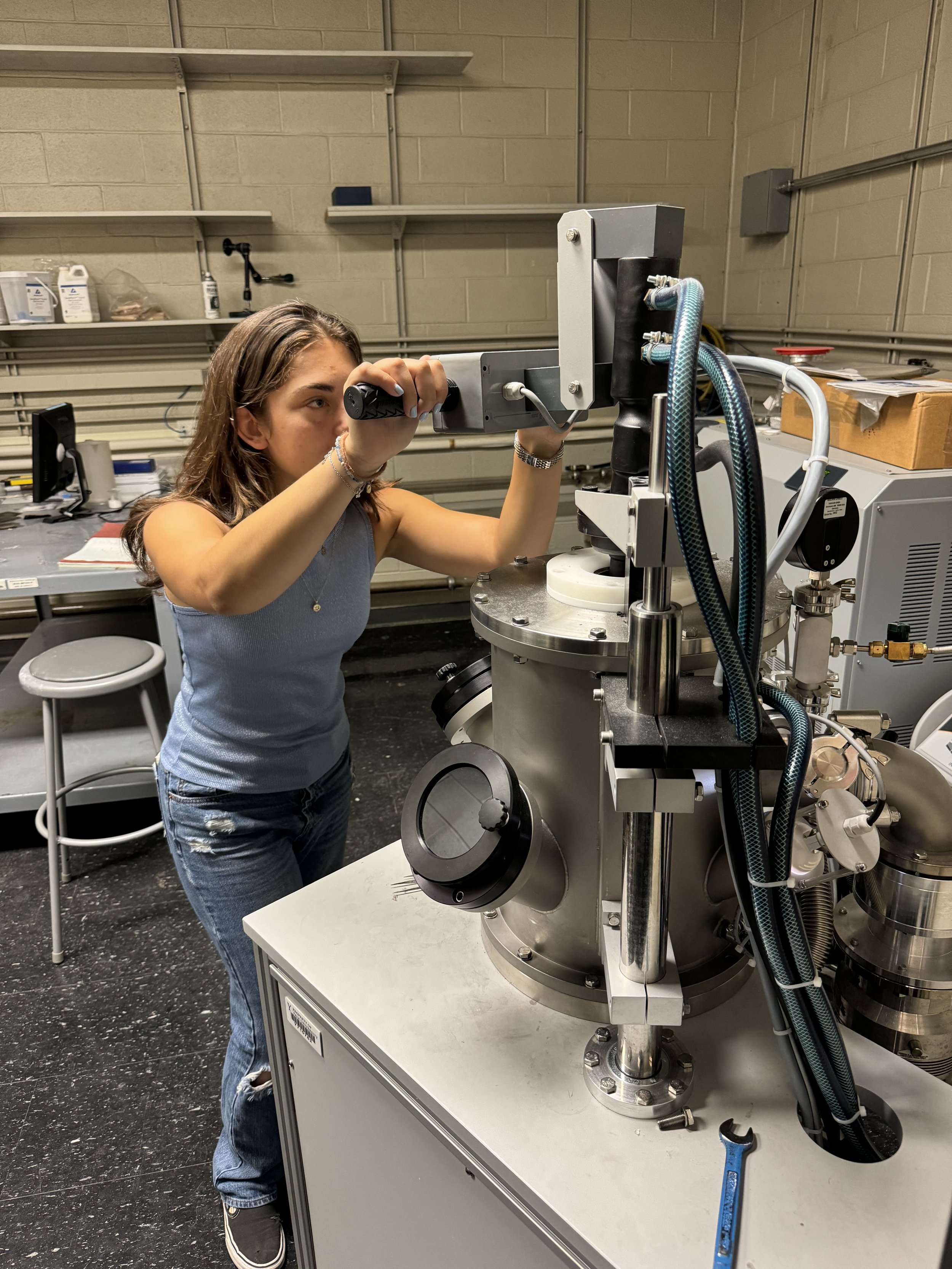

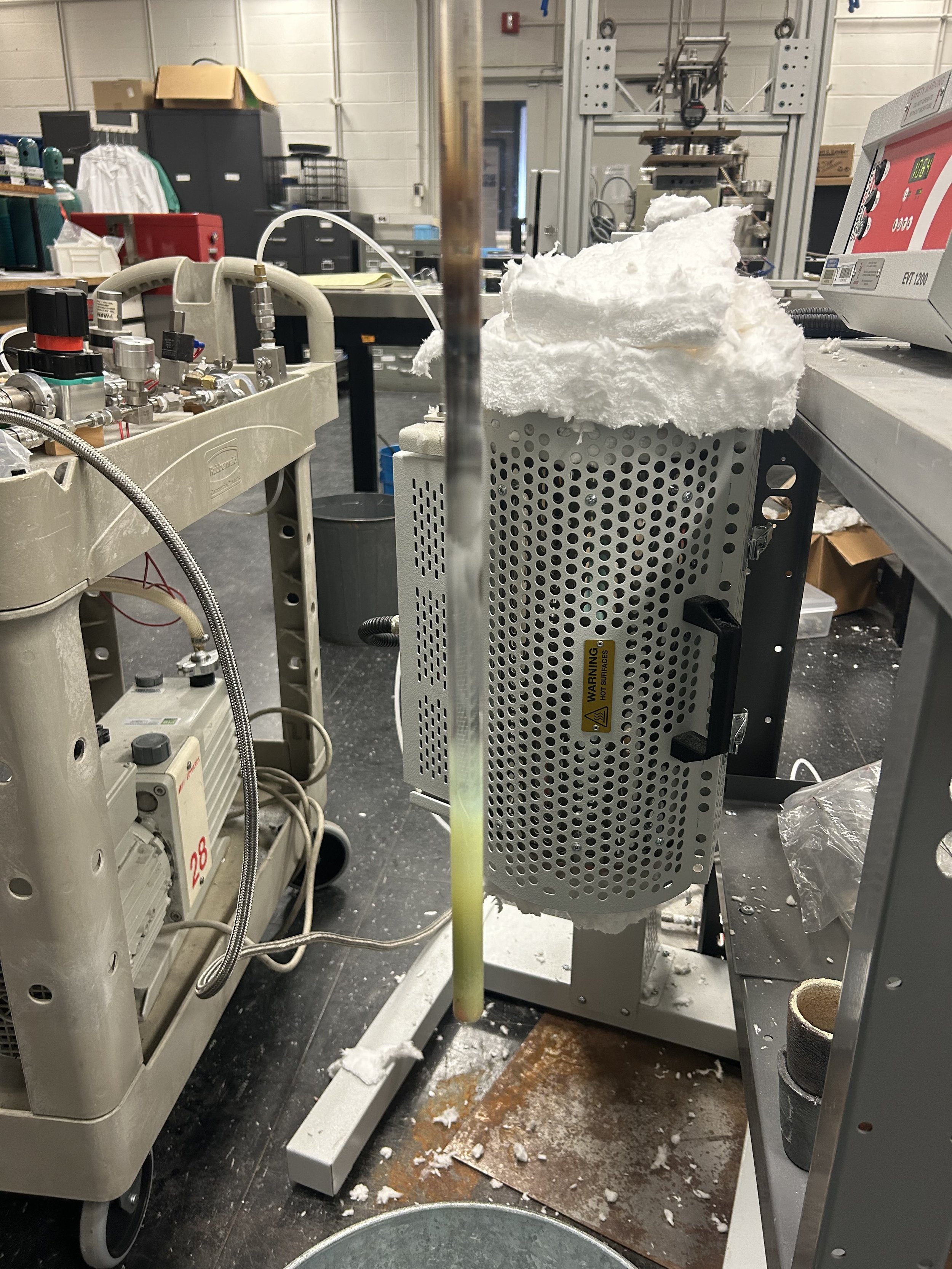

Refilling liquid nitrogen in TEM

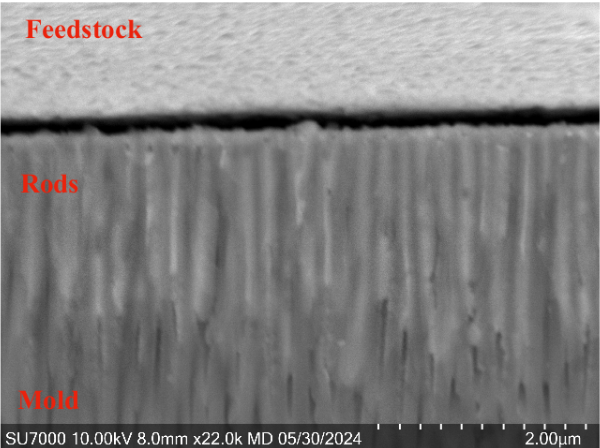

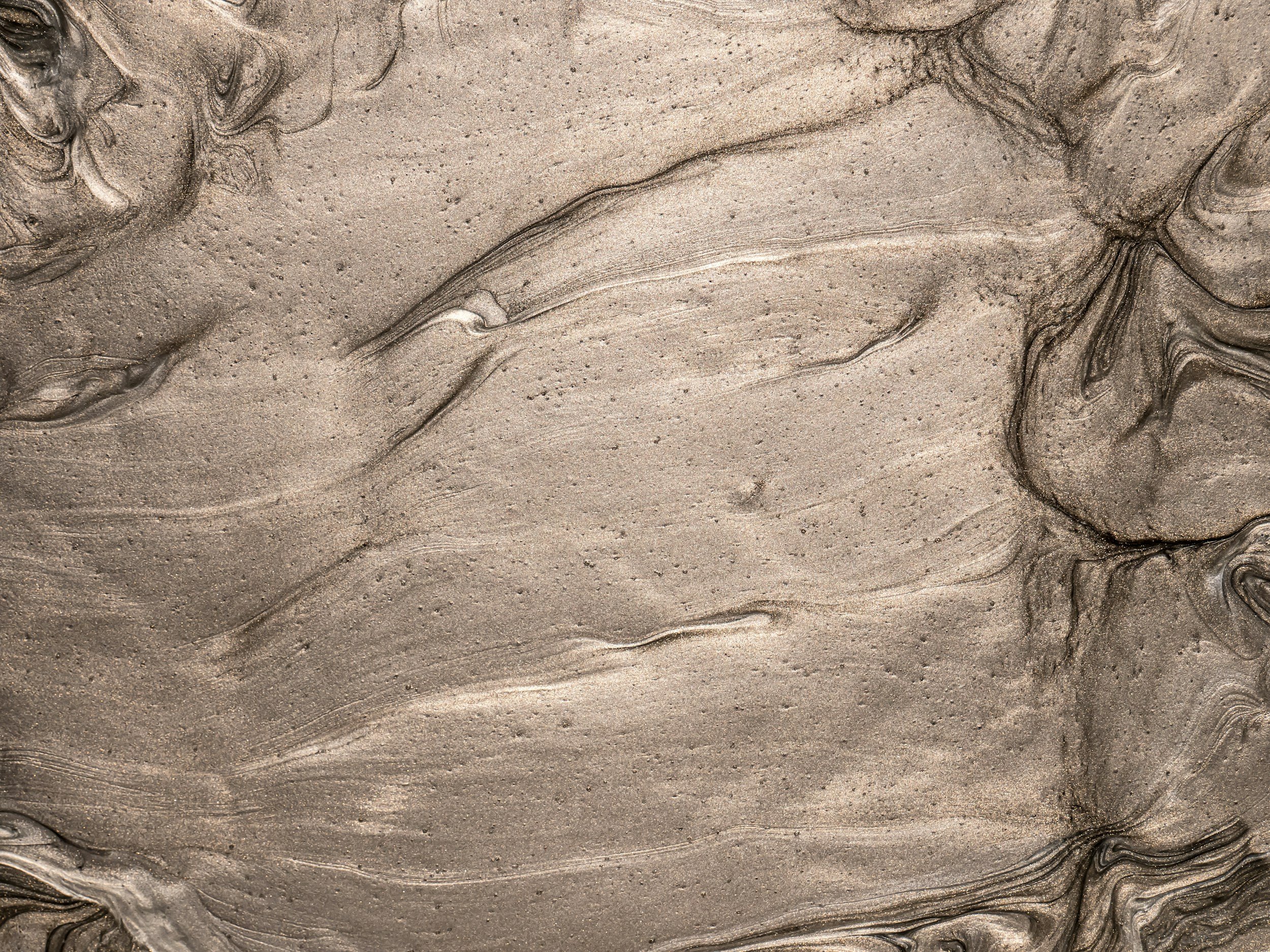

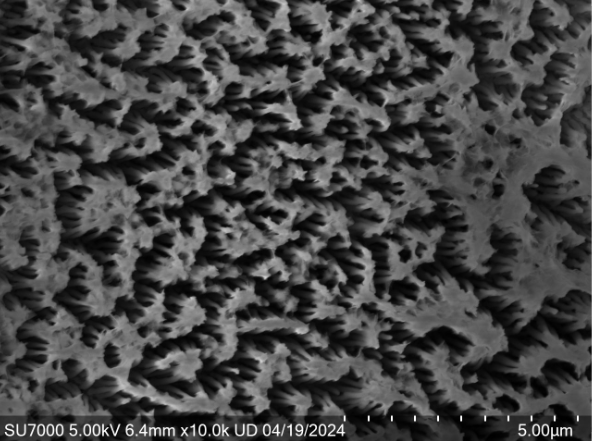

Cantor Alloy SEM image of sample pressed at 500 C for 1 hours at a force of 12kN with an 80nM mold

Sample are being pressed and heated with radio-frequency coil

Hydraulic pressing machine actively pressing a sample

SEM nanorods results

Annealed Cantor Alloy and noticing what is thought to be Mn residue on the tube

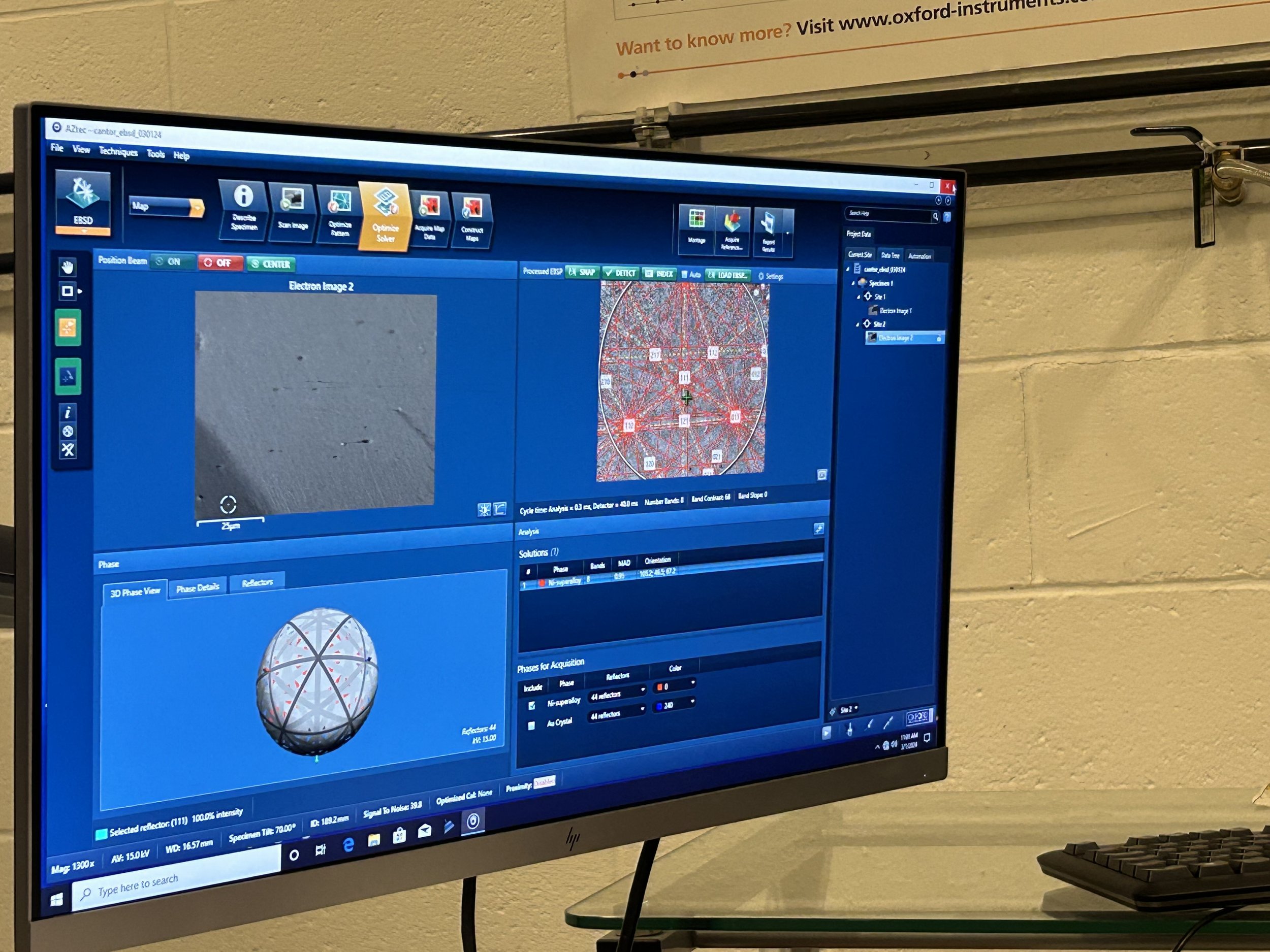

Attempting to EBSD the Canto Alloy

Visual of heated sample using RF coil

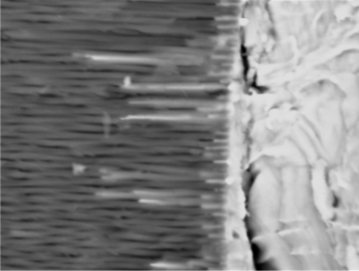

SEM nanorods result

SEM nanorods result

First mini-arc melting casting of Cantor Alloy

Sample Example 1: Pressed at 800C for 1 hour with a force of 4Kn onto an 80nM mold

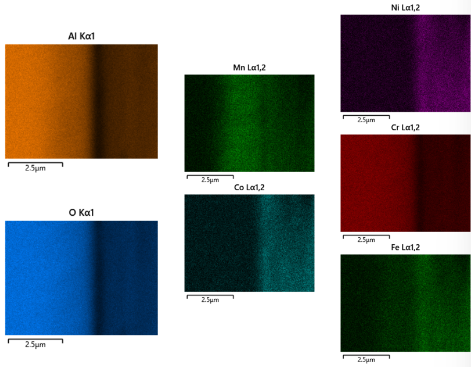

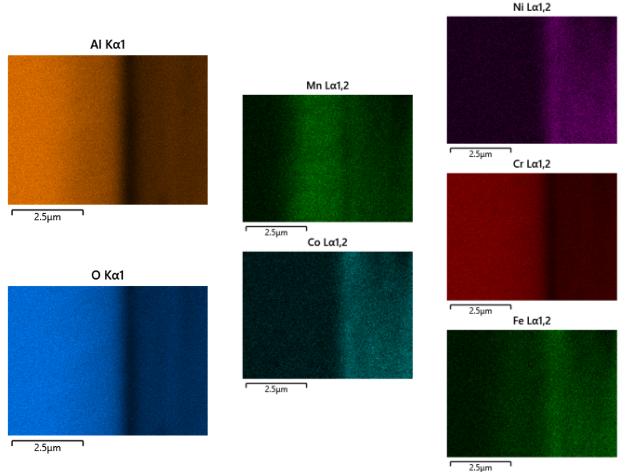

Sample Example 1: EDX results

Sample Example 2: Pressed at 800C for 1 hour with a force of 20Kn onto an 80nM mold

Sample Example 2: EDX results

The first SEM-EDX sample was pressed at 800C for 1 hour with a force of 4Kn onto an 80nM mold. It displays good growth of rods, measuring up to 2uM, and solidifies rods are Mn rich. The second set of SEM-EDX was pressed at 800C for 1 hour with a force of 20Kn onto an 80nM mold. It as well displays great rod growth, measuring up to 1uM. Though there was too much charge to get a good mapping, the rods continue to be Mn rich, but additionally show the feedstock is Mn and Cr poor.