April 2024

Synthetic lubricants like and motor oil are vital to the function of everyday machines, from car engine blocks to heavy-duty machinery to hand-held power tools. In this project we hoped to characterize the viscosity of a synthetic lubricant at room temperature and at application temperatures using the Rheometer. Additionally, to characterize the effect of particle contaminants on the viscosity of the lubricant.

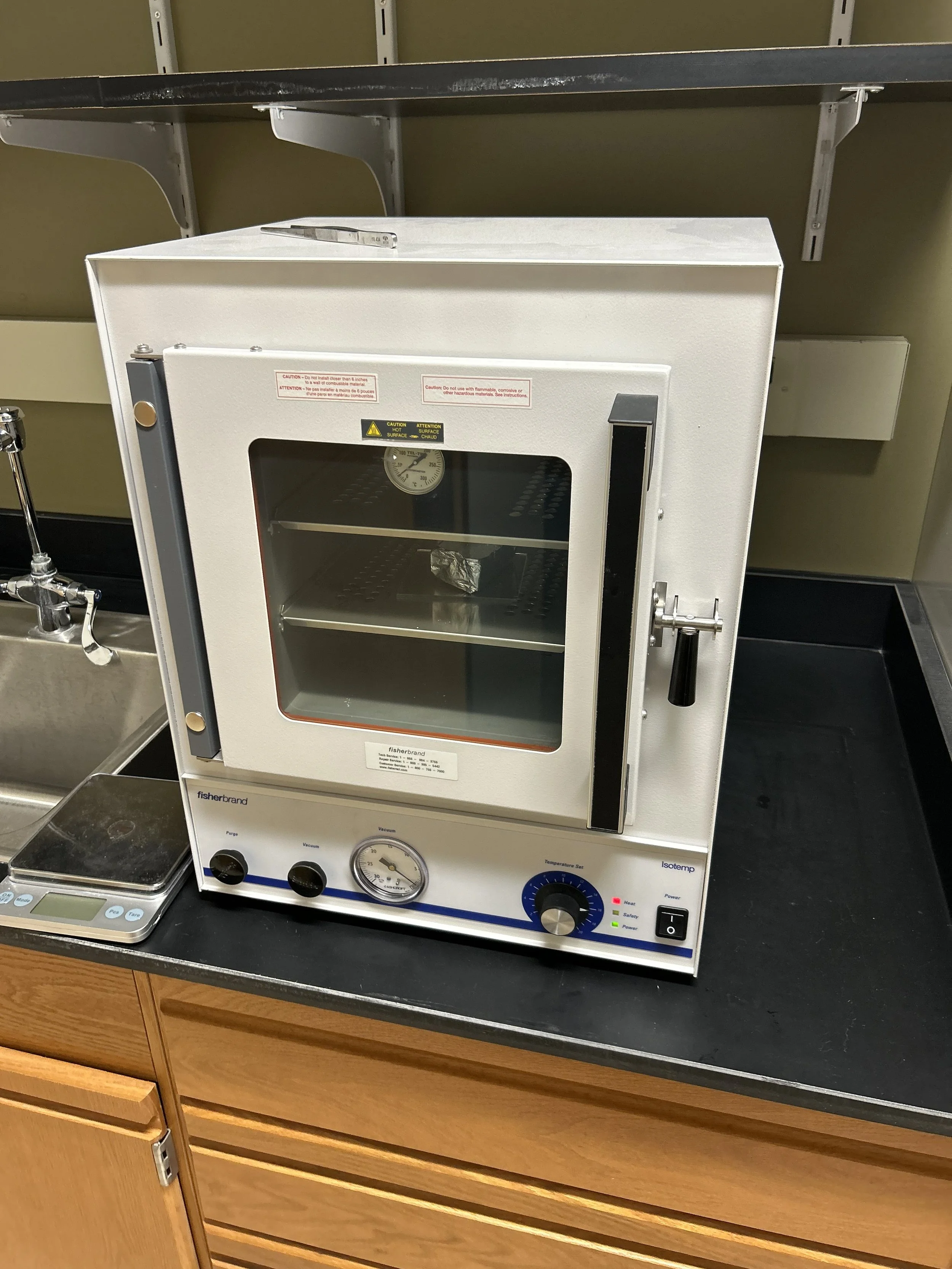

After heating the 10-micron silica particles at 100-120 °C for 30 min to remove moisture with a Vacuum Oven, we measured 20 wt% silica and 50 wt% silica samples and mixed them with our motor oil respectively. We then ran the rheometer tests at room temperature with the control, 20 wt%, and 50 wt% samples at a shear rate range from 10e-5 to 10e3. Following that, we ran tests at 100 °C with the 20 wt% and 50 wt% samples at a shear rate range from 10e-5 to 10e3.

Group-mate pouring sample into the Rheometer

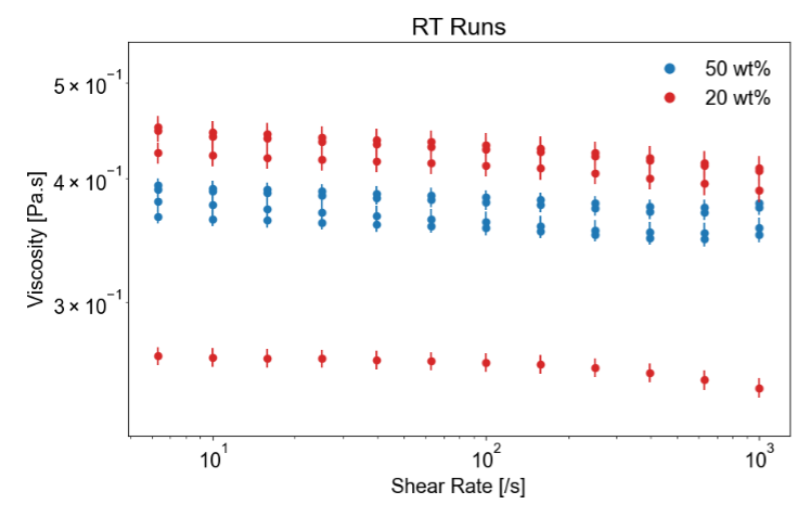

Shear Rate vs Viscosity graph at room temperature

Vacuum oven used to remove moister from similar particles

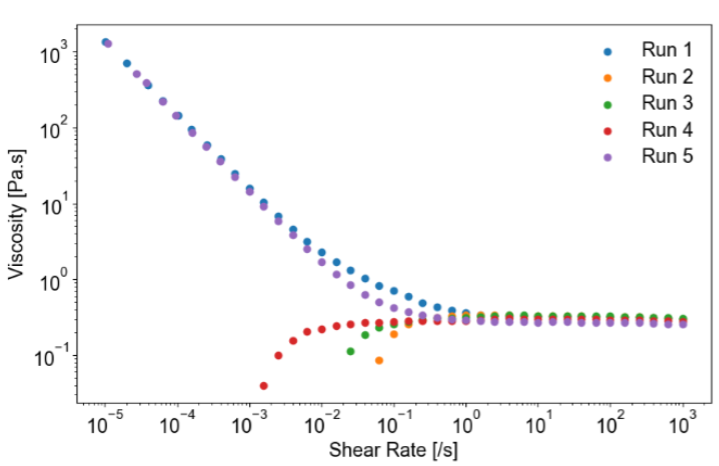

Shear rate vs Viscosity graph at room temperature

Fun picture of our group presentation at the end of the semester

After conducting this research, we found that viscosity of this synthetic motor oil increases as an increase in particle contaminants increased. When introduced to higher temperatures the increase was more significant due to the thermal conductivity of the silica particles vs. the motor oil. The potential under or over filling of the testing plates played a big role in our results and demonstrated unrealistic viscosity vs shear rate results.

This model provides a good example of the effects of contaminants present anywhere moto oil is used. Further real-world applicable testing would involve using iron shavings instead of silica particles and running future tests with concentric cylinders instead of flat plates to better hold the sample and minimize potential under / over filling.