Fall 2023

A stirling engine uses the changes in pressure and temperature to convert heat into mechanical work through compression and expansion. Making an at-home version with cans is a common way to understand this process and is often tasked in thermodynamics classes.

The goal of this engine is to work with just a hot plate placed underneath, and perhaps add ice to the top of the engine if needed. Students were to use their knowledge of thermodynamics in parallel with this project, and gain hands-on manufacturing experience at the same time.

The beginning process: creating sheets of metal by opening up soda cans

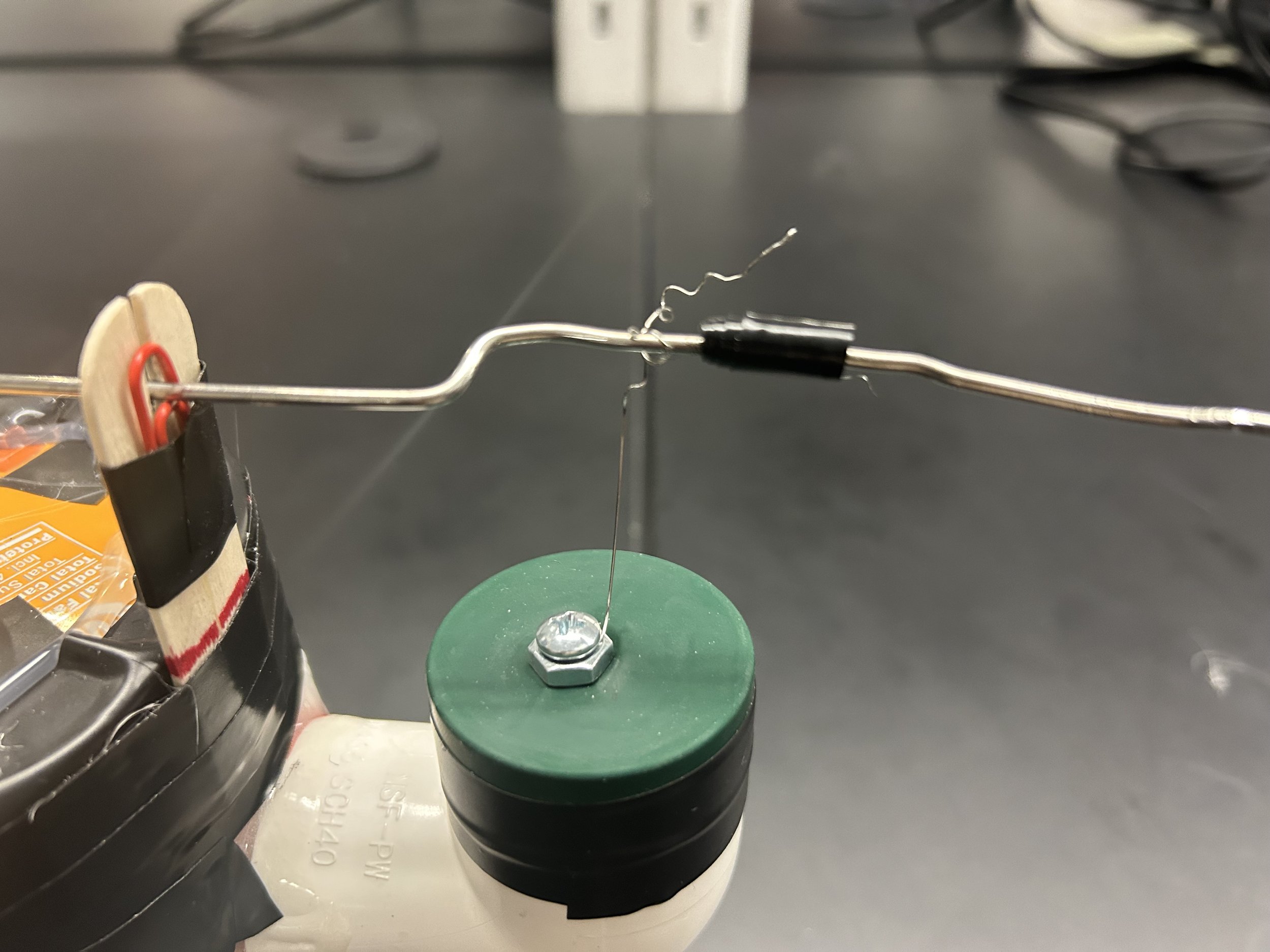

Makeshift piston out of the tops of the bigger can and inserting steel wool to trap heat

Attaching an elbow pipe to the can using epoxy

Created a power piston

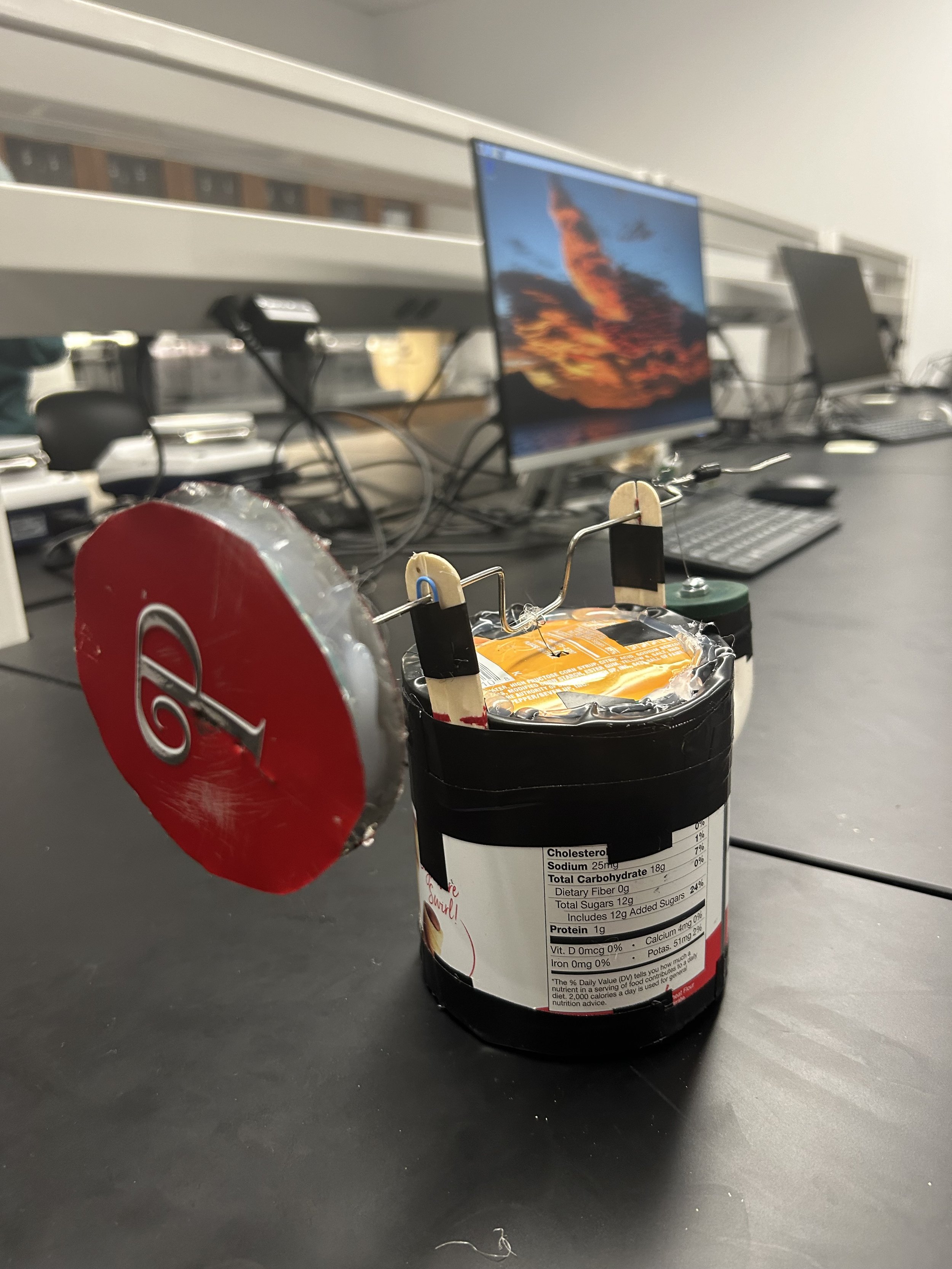

A very DIY stirling engine ready for testing

With cans and frequent trips to different on-campus machine shops, I first created the piston out of the top and bottom of the can, and connecting them through a series of bent wires. I then cut a hole in the side of the can to attach a pvc elbow pipe for the power piston. I learned how to use epoxy, manipulate metal, and played around with pumps/piston proportions.

Though the engine was not able to function given my limed amount of time, I now know that I needed to downsize the scale of my engine and needed to prioritize more creating an air-tight system.